Main menu

You are here

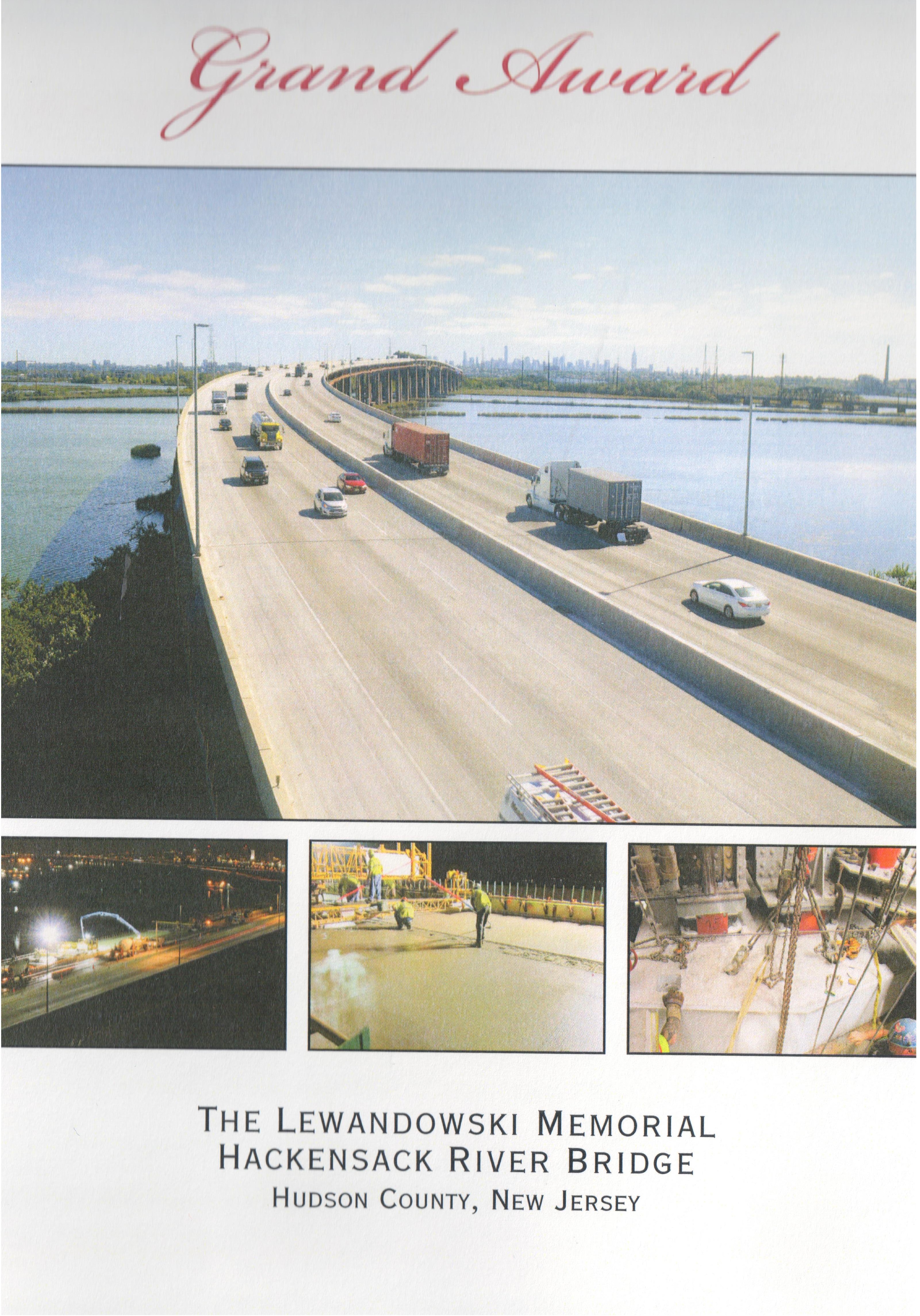

RIME Team wins Grand Award with the Project Team for the Lewandowski Memorial Hackensack River Bridge

Date: on 5/14/15

The RIME Team received a prestigious award during the 52nd Annual NJ Concrete Awards for New Jersey’s Outstanding Concrete Project of the Year 2014. The project won the Grand Award with Dewberry as the lead designer and with RIME as the structural health monitoring (SHM) and field testing laboratory.

List of researchers involved in this project

Hani Nassif, PE, Ph.D. Director of RIME Group

Dan Su, Ph.D. Post-doctoral Associate

Chaekuk Na, Ph.D. Research Associate

Miguel Beltran, Graduate Research Assistant

Peng Lou, Graduate Research Assistant

Adi Abu-Obeidah, Graduate Research Assistant

Michael Salvador, Graduate Research Assistant

Samer Rabie, Graduate Research Assistant

Dalex Gonzalez, Graduate Research Assistant

Ope Adediji, Graduate Research Assistant

Involvement of RIME Group

- Develop FE model for typical bridge span

- Collect structural responses as well as traffic data

- Develop construction specs for the construction

- Evaluate the performance of HPC concrete deck at early age for various loading scenarios and structures

- Technical support for structural design

- Evaluate the effect of tie-down (50% vs. 100%) on the debonding of the rebar

- Instrument various sensors for the structural health monitoring

- Monitoring the bearing movement using various state-of-the-art technologies

- Collect and test concrete samples for the quality control

About the Lewandowski Memorial Hackensack River Bridge

The Lewandowski Memorial Bridge is a six-lane structure that carries over 110,000 vehicles each day. The reconstruction effort required over 20,340 cubic yards for the high-performance concrete deck, median barrier and parapets; 998 cubic yards for at-grade median barrier; and 325 cubic yards for pre-cast concrete pedestals.

High-performance concrete was the mix design of choice for he bridge deck, with a minimum compressive strength of 4,500 psi. Pre-cast concrete pedestals were used as part of the seismic upgrade at 148 locations. With pedestals as much as 27-feet tall, pre-cast concrete was determined to be easier to detail and more economical to manufacture than steel, especially considering the wide range of heights and sizes required.

Utilizing a concrete deck system rather than steel provided a substantial increase in carrying capacity as the concrete deck was made composite with the supporting steel superstructure.

Owner: New Jersey Turnpike Authority

Design Engineer: Dewberry Engineers, Inc.

Design Engineer Sub-consultant: HNTB Corporation

General Contractor: The Conti Group

Construction Manager: Jacobs Engineering Group

Concrete Contractor: Atlas Concrete Corp.

Ready-Mix Concrete Supplier: Eastern Concrete Materials, Inc.

Cement Supplier: Lafarge North America

Precast Supplier: Northeast Precast

Fine, Coarse & Light-wt Agg.: Eastern Concrete Materials, Inc.

Admixtures: BASF Admixture Systems

Pumping Contractor: Alexander Wagner Co., Inc.

Testing Laboratories: Key-Tech Laboratories

RIME Group

Pozzolan Supplier: Eastern Concrete Materials, Inc.

Reinforcing Steel Supplier: CFS Steel Company